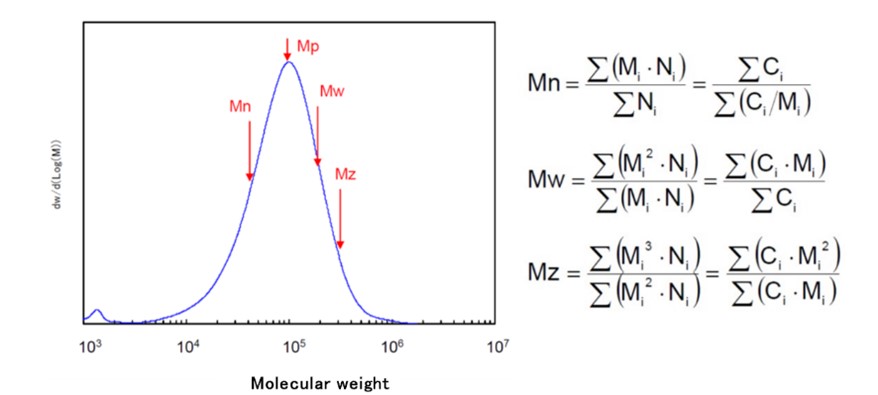

Figure 6 shows a GPC chromatogram of a polymer, where Mn, Mw, Mz, and Mp are the number-average molecular weight, weight-average molecular weight, Z-average molecular weight and peak top, respectively. Here, N is the number of polymer molecules, M is the molecular weight, and C is the sample concentration, C(wt./vol.) = M・N. Mn is the simple arithmetic mean, Mw is the weighted mean using molecular weight as a weight, and Mz is the weighted mean using the square of molecular weight as a weight. Mw/Mn = PDI is used as an index to evaluate the spread of molecular weight (molecular weight distribution); the smaller the PDI, the narrower the molecular weight distribution.

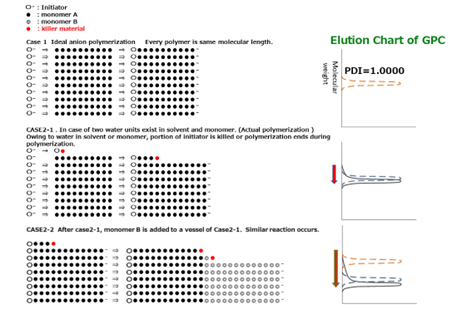

Figure 7 shows a schematic diagram of why the PDI becomes wider when block copolymers are synthesized by anionic polymerization. Case 1 is the polymerization under the so-called ideal condition where there is no killer material at all in the reaction system. In this case, the initiator and the carbanion are not inactivated during the polymerization process, so the homopolymer with the designed molecular weight is obtained. The PDI is 1.0000, as in the case of homo polymer. In Case 2-1, the molecular weight of Polymer A is larger than the designed molecular weight because some initiators and the growing ends of the A chain are deactivated by the monomers, solvents, and a few killer materials present in the polymerization environment, resulting in a distribution.

Case 2-2 shows the polymerization of a diblock polymer. The unreacted killer material attacks the growing ends of the A chain and the growing carbanion of the B chain, causing the deactivated polymer to accumulate in the low molecular weight region. This eventually remains in the block copolymer and becomes a troublesome impurity.