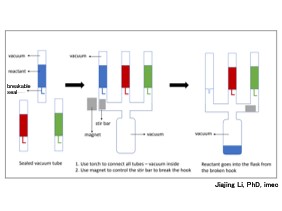

As Figure 12 shows how the polymerization equipment is assembled with a hand burner, anionic polymerization is usually performed using glass processing techniques, which require at least two to three years of training to master. This is a barrier to entry, and there are only a few anion polymerization researchers in the world. It is hell, especially during the hot summer months.

The initiator, solvent, monomers, and polymerization stopper used in anionic polymerization are melt-sealed in a glass vessel fitted with a breakable seal. This is attached to the polymerization vessel, and the entire apparatus is maintained in a high vacuum by a diffusion pump or turbo molecular pump, in which anionic polymerization is performed. Polymerization is carried out by breaking down the breakable seal by moving the stir bar, which is placed inside the apparatus in advance, with a magnet outside. This allows anionic polymerization to be carried out while maintaining a high vacuum.

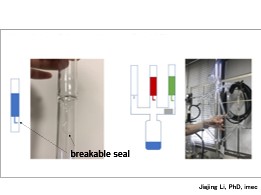

The hook-shaped glass shown in Figure 13-2 is a breakable seal. Anionic polymerization using this glass is called the breakable seal method, and is one of the most important techniques for anionic polymerization researchers. On the other hand, it is not easy to make a breakable seal that does not break during various operations but breaks reliably when necessary, and it requires considerable effort, patience, and discipline to be able to make it by oneself.