Anionic polymerization using the breakable seal method is a rare method that can synthesis polymers with molecular weight, molecular structure and sharp PDI according to molecular design, but it is difficult to synthesis a large number of samples. Therefore, we developed a 5L-scale polymerization apparatus consisting of SUS316L (composite electropolished) and QVF glass as a preliminary step for mass production and attempted to synthesis DSA. Figure 14 shows a part of the apparatus, which is a completely original product designed and manufactured by me. All parts are standardized and communized, so as long as you can tighten the bolts and nuts, you can learn anionic polymerization technology in about a month. The specifications of the equipment are (1) attainable vacuum < 1×10-6 Pa and (2) helium leak rate < 5×10-9 atm.cc/sec. (2) means that if the inside of the polymerization equipment is sealed in a vacuum, it would take more than 3000 years for 1 cc of air to leak in from outside the equipment

Anionic polymerization using a 5L polymerize initially reached only about PDI = 1.1, but through two-step purification of the monomer and improvement of the equipment, it was able to reach a level almost comparable to the breakable seal method. Currently, we are making efforts to increase the polymerization concentration to 30% or more in order to raise the pot yield. Incidentally, 5% is the standard for the breakable seal method.

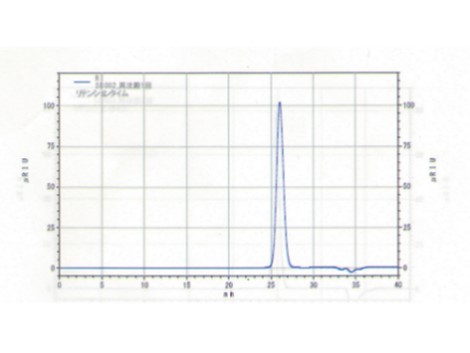

Figure 15 shows an experimental synthesis of P(St-b-BuOSt), where a polymer with Mw=10,000 and PDI=1.02 can now be synthesized reproducibly. Incidentally, PDI (GPC) = 1.02 corresponds to PDI < 1.003 in MALS and TOF-MS. In the future, we would like to adopt the absolute molecular weight value.