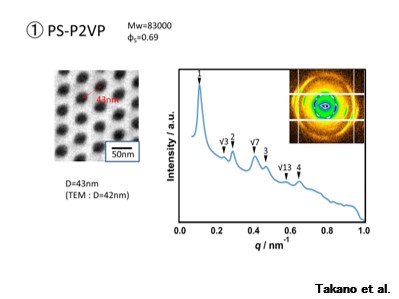

Figure 34 shows TEM images and SAX data of PSt-b-2VP, which was presented to several semiconductor manufacturers who requested DSA of about Ch = 50 nm.

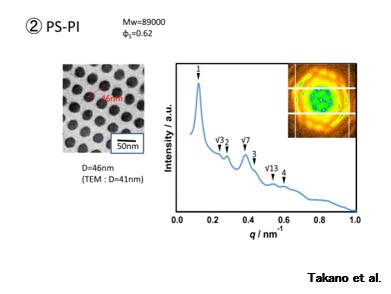

Figure 35 shows the data for PSt-b-PI; the inclusion of a rubber component in the DSA would make dry etching easier. On the other hand, when we tried to apply these data to conventional PSt-b-PMMA, we found that we needed Mw = 1.8×104 to achieve Ch = 50 nm. When we actually made and supplied the polymer, it was highly evaluated.